The automotive industry has long grappled with the delicate interplay between form and function, and nowhere is this tension more apparent than in wheel design. For decades, engineers and designers have engaged in a silent tug-of-war between aerodynamic efficiency and visual appeal, each pushing the boundaries of what's possible while constrained by the other's demands. This dance between airflow management and aesthetic statement continues to evolve as new materials and manufacturing techniques emerge.

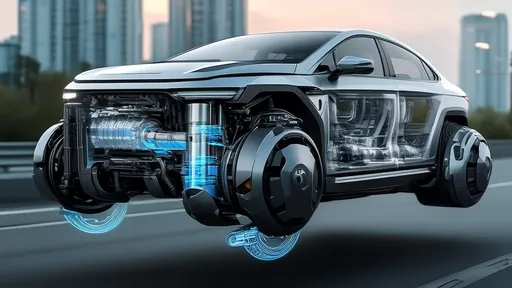

At first glance, the wheel might seem like a simple component - round, metallic, and utilitarian. But modern alloy wheels represent one of the most complex design challenges in vehicle development. The competing priorities create what industry insiders call "the wheel paradox": the very features that make wheels visually striking often work against their aerodynamic performance, while the most efficient designs frequently appear dull or uninspired to consumers.

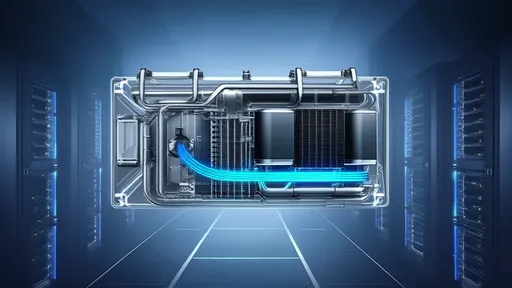

The physics of wheel aerodynamics reveals why this balance proves so difficult to achieve. As a vehicle moves, air interacts with the rotating wheels in complex ways, creating turbulence that can account for up to 25% of total drag. Designers must carefully consider spoke shape, rim depth, and even the microscopic texture of surfaces to manage this airflow. Computational fluid dynamics simulations now allow engineers to test hundreds of iterations before physical prototypes are built, but each adjustment for efficiency carries aesthetic consequences.

Automotive designers speak of wheel designs as having a "visual weight" that must complement the vehicle's overall proportions. A wheel that's too visually heavy can make a car appear sluggish, while one that's too light might seem insubstantial. The curvature of spokes, the angle of their placement, and the relationship between open and closed areas all contribute to this perception. Some manufacturers have developed signature spoke patterns that serve as brand identifiers, proving that aesthetics can carry as much importance as technical specifications in consumer decisions.

Material science breakthroughs have enabled new solutions to this design dilemma. Forged aluminum alloys now allow for thinner, stronger spokes that maintain structural integrity while improving airflow. Carbon fiber wheels take this further, permitting shapes that would be impossible with metal. These advanced materials come with higher costs, but for performance vehicles where every watt of energy matters, the investment often proves worthwhile. The weight savings alone can dramatically improve handling and acceleration while simultaneously allowing for more daring designs.

The electric vehicle revolution has added new urgency to aerodynamic wheel design. With range anxiety remaining a consumer concern, automakers can't afford unnecessary energy losses. Many EV manufacturers have adopted wheel designs that would have been unthinkable a decade ago - nearly flat surfaces with minimal openings, covered with aerodynamic caps. These designs often employ active elements that change configuration at different speeds, attempting to reconcile static beauty with dynamic efficiency. The results challenge traditional notions of wheel aesthetics while demonstrating that beauty can emerge from pure functionality.

Cultural influences play a surprisingly large role in wheel design preferences. European manufacturers tend to favor understated elegance with intricate machining details, while American consumers often prefer bold, muscular designs with prominent spokes. Asian automakers frequently strike a balance between the two, incorporating technological elements into visually clean designs. These regional preferences force global manufacturers to develop multiple wheel options for the same vehicle platform, further complicating the design process.

Aftermarket wheel companies have capitalized on the aesthetic desires of consumers, often prioritizing looks over efficiency. The popularity of oversized wheels with low-profile tires demonstrates that for many buyers, appearance trumps functionality. This market reality pressures OEM designers to create factory wheels that can compete with aftermarket options in terms of visual impact while still meeting corporate efficiency targets. The result has been an arms race of wheel design innovation across the industry.

The human element of wheel design shouldn't be underestimated. Focus groups and consumer clinics consistently show that wheels rank among the top three visual factors in vehicle purchase decisions. This emotional connection to wheel design explains why automakers invest millions in development and why consumers will pay thousands for premium wheel options. The psychological impact of a beautifully designed wheel can make an entire vehicle feel more premium, powerful, or sporty - regardless of its actual performance characteristics.

Looking ahead, wheel design faces new challenges from emerging technologies. Autonomous vehicles may prioritize completely different aesthetic values, potentially making current designs obsolete. Augmented reality interfaces could transform wheels into display surfaces, adding another layer to the design equation. Whatever the future holds, the fundamental tension between airflow management and visual appeal will persist, ensuring that wheel designers remain at the forefront of automotive innovation. Their solutions will continue to shape not just how cars perform, but how they make us feel when we see them on the road.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025