The automotive industry is undergoing a silent revolution beneath the wheels of modern vehicles, where magnetorheological (MR) damping technology is redefining what constitutes a smooth ride. Unlike traditional passive suspension systems that simply react to road conditions, these intelligent dampers anticipate and adapt to terrain changes with almost clairvoyant precision. At the heart of this transformation lies a mysterious fluid that transforms its viscosity in milliseconds when exposed to magnetic fields, creating what engineers poetically describe as "liquid physics defying its own nature."

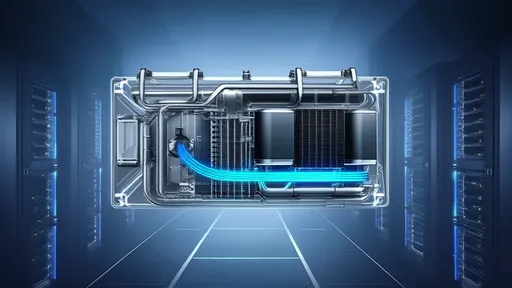

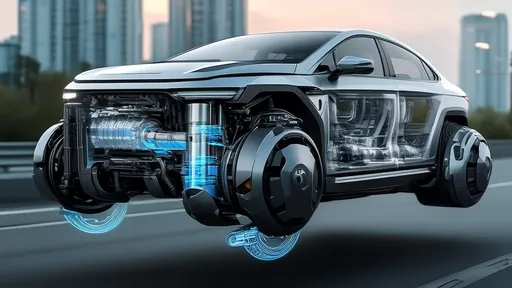

Walking through the laboratory of a major automotive supplier reveals rows of unassuming metal tubes that conceal this technological marvel. When disassembled, the damper's internal structure appears deceptively simple - a piston rod, some coiled wire, and that enigmatic silvery-gray MR fluid. Yet this humble combination enables luxury vehicles to glide over cobblestones like they're floating on air while simultaneously allowing sports cars to attack hairpin turns with race-track precision. The secret lies in the fluid's iron particles, which align into fibrous structures when energized, instantly changing the resistance to piston movement within the damper.

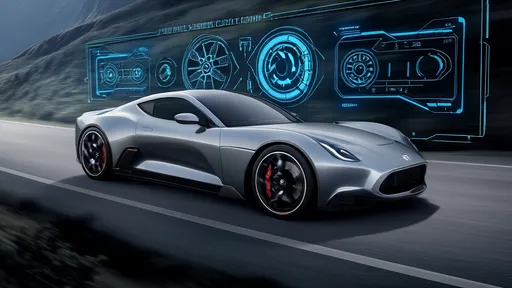

Real-world performance of these systems borders on witchcraft to first-time observers. On a test track, engineers demonstrate how a vehicle equipped with MR dampers maintains composure over simulated potholes that would send conventional suspensions into chaotic oscillations. More impressively, the same car demonstrates minimal body roll during aggressive slalom maneuvers, all without the bone-jarring stiffness of traditional performance suspensions. This chameleon-like adaptability stems from continuous monitoring by up to 20 vehicle sensors feeding data to the suspension control unit, which can adjust each damper independently up to 1,000 times per second.

The evolution of MR fluid technology reads like a materials science detective story. Early formulations in the 1990s suffered from particle settlement issues - the iron particles would gradually sink to the bottom of the fluid reservoir, much like sediment in a fine wine. Modern iterations employ nano-engineered particles with specialized coatings and surfactant additives that maintain homogeneous distribution for the lifetime of the vehicle. These advancements have pushed service intervals beyond 150,000 miles in some applications, effectively making the system maintenance-free for most owners.

Manufacturing these dampers requires precision that would make Swiss watchmakers nod in approval. The electromagnetic coils must be wound with tolerances measured in microns, as any variation affects magnetic field consistency. Fluid reservoirs are laser-welded in oxygen-free environments to prevent contamination, and each unit undergoes rigorous testing that subjects it to everything from Arctic cold to desert heat before installation. What emerges from this process is a component that operates flawlessly whether navigating icy Montreal streets or Death Valley's scorching tarmac.

Interestingly, the automotive sector isn't the only beneficiary of this technology. Civil engineers have begun implementing large-scale MR dampers in earthquake-resistant building designs, while aerospace applications range from helicopter rotor blade stabilization to spacecraft landing systems. Even niche markets like high-end gaming chairs and hospital surgical tables have adopted scaled-down versions of the technology. However, it's in passenger vehicles where MR dampers have found their true calling, particularly in the luxury segment where brands like Cadillac and Ferrari have made them centerpieces of their driving experience narratives.

The computational brain behind these systems represents another marvel of modern engineering. Early control algorithms relied on relatively simple lookup tables that matched damper settings to basic vehicle dynamics measurements. Today's systems employ adaptive machine learning models that continuously refine their responses based on driving style, road conditions, and even predictive data from navigation systems. Some experimental setups now incorporate camera-based road scanning that prepares the suspension for upcoming imperfections much like a skier anticipates moguls on a downhill run.

Energy consumption of these systems might surprise those imagining power-hungry electromagnets draining vehicle batteries. In reality, the current required to activate the MR effect is minimal - typically less than 2 amps per damper during aggressive operation. Smart power management systems pulse the current only when needed, and some designs even recover energy from damper movement to partially offset electrical demands. This efficiency enables the technology to appear not just in high-performance vehicles, but increasingly in mainstream models where fuel economy remains paramount.

Looking toward the horizon, MR damping technology continues to evolve in fascinating directions. Material scientists are experimenting with hybrid fluids containing multiple particle types that could enable even finer control over damping characteristics. Some prototypes explore incorporating piezoelectric elements that would make the dampers self-sensing, eliminating separate position sensors. Perhaps most intriguing are concepts pairing MR dampers with air suspension systems, creating hybrid setups that could offer unprecedented combinations of comfort and control.

The human impact of this technology often gets overlooked in technical discussions. For drivers with chronic back pain, the difference between conventional and MR-equipped suspensions can be life-changing, transforming painful commutes into tolerable journeys. Families report reduced motion sickness in children during long road trips, while emergency responders benefit from improved stability when navigating uneven terrain at high speeds. These real-world benefits explain why what began as a niche technology for luxury vehicles is rapidly democratizing across price segments.

As autonomous vehicles mature, MR damping takes on new importance. Without a human driver to compensate for suspension imperfections, self-driving cars require exceptionally stable platforms for sensor operation and passenger comfort. The predictive capabilities of modern MR systems align perfectly with autonomous technology's needs, potentially making them standard equipment rather than luxury options in the driverless future. Some industry observers predict that by 2030, over 60% of new vehicles will feature some form of semi-active damping, with MR technology leading the charge.

The road ahead for magnetorheological damping appears as smooth as the ride quality it enables. With each generation, the systems become more sophisticated, more reliable, and more accessible - a rare trifecta in automotive innovation. From its military origins to its current mainstream applications, this technology exemplifies how materials science breakthroughs can quietly revolutionize everyday experiences. As vehicles continue evolving into rolling technology platforms, the humble damper's transformation into a smart, adaptive system serves as a reminder that sometimes the most profound innovations happen out of sight, beneath our feet, in the dark spaces between road and rim.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025