The pursuit of performance in track-focused vehicles has always pushed engineering boundaries, particularly when it comes to cooling systems operating under extreme conditions. As enthusiasts and professional drivers demand more from their machines, the concept of overclocking cooling systems has emerged as a critical area of innovation. Unlike traditional street applications, track mode scenarios subject components to sustained high loads, making thermal management not just an afterthought but a central pillar of reliability.

At the heart of this challenge lies the delicate balance between extracting maximum performance and maintaining system integrity. Overclocking a cooling system—whether through increased pump speeds, aggressive fan curves, or optimized coolant flow—can yield significant gains in power delivery and consistency. However, the margin for error shrinks dramatically when operating near thermal limits. Engineers now employ advanced simulations and real-world telemetry to map failure points, often discovering that small adjustments in airflow or coolant composition can mean the difference between a podium finish and catastrophic engine failure.

The materials science revolution has quietly transformed what's possible in cooling system overclocking. Nano-enhanced coolants with superior heat transfer properties now work in tandem with 3D-printed aluminum radiator cores featuring fractal-inspired geometries. These innovations don't simply improve cooling capacity; they change how heat moves through the entire system. During endurance events, where conventional systems might fade after hours of abuse, these next-generation solutions maintain remarkably stable temperatures even as drivers push lap after punishing lap.

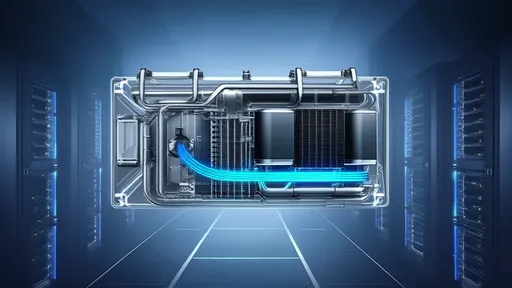

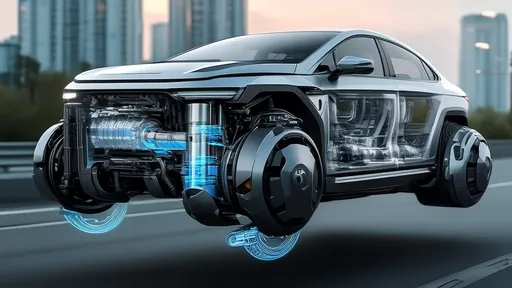

Electrification adds another layer of complexity to the cooling equation. High-performance hybrid systems generate heat not just from combustion but from battery packs and power electronics operating at the edge of their capabilities. Liquid-cooled inverters and phase-change materials for battery temperature regulation represent just two fronts in this multidimensional thermal battle. The cooling systems handling these dual demands must be overclocked with surgical precision, as the thermal profile of an electric motor differs fundamentally from that of a turbocharged V8.

Data acquisition has become the unsung hero of reliable cooling system overclocking. Where teams once relied on basic temperature gauges, modern systems monitor heat flux across dozens of points at sampling rates that would make a meteorologist blush. This torrent of real-time data feeds self-adjusting algorithms that can predict thermal runaway before it occurs, automatically dialing back power or increasing coolant flow to stay within safe operating windows. The best systems accomplish this without the driver noticing—maintaining lap times while preserving machinery.

Perhaps the most counterintuitive revelation in recent years involves embracing controlled inefficiency. Some championship-winning teams have discovered that running cooling systems at 100% capacity actually decreases reliability compared to operating at 90-95% with intelligent headroom management. This paradigm shift acknowledges that thermal systems, like athletes, perform best when not constantly redlined. The art lies in determining exactly where that sweet spot resides for each unique combination of vehicle, track, and environmental conditions.

The human factor remains irreplaceable despite all technological advancements. Veteran crew chiefs still interpret subtle clues—the smell of overheated fluid, minute changes in exhaust note, or even the way tire wear patterns correlate with cooling performance. These empirical observations complement sensor data, creating a holistic approach to pushing cooling systems to their limits without crossing into dangerous territory. It's this marriage of art and science that separates competent cooling system overclocking from truly championship-caliber execution.

Looking ahead, the next frontier may involve biomimicry—cooling systems that adapt like living organisms. Early research into shape-memory alloys that alter radiator fin geometry based on temperature shows promise, as do self-healing coolant passages inspired by human vascular systems. Such innovations could redefine the very concept of overclocking, transforming cooling systems from static components into dynamic, intelligent thermal partners. For now, teams continue extracting every ounce of performance from existing technologies while preparing for the coming revolution in thermal management.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025